Summary: This article discusses the origin of Lean Six Sigma (LSS), how it works and why it is important for government employees.

Background – Total Quality Management

Lean Six Sigma (LSS) has its roots in Total Quality Management (TQM). TQM is a management approach that began in the 1950s and was used by the Defense Logistics Agency in the 1990s to improve the quality of military parts and systems. Adapted from the manufacturing industry, it morphed into a management philosophy crossing multiple functions to put processes in place to reduce waste and improve customer service. The federal government has moved its emphasis from TQM to LSS.

Six Sigma

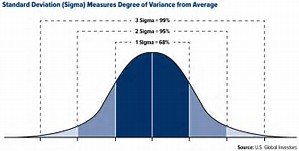

You may not know it, but Six Sigma is a statistical term. Let me explain: if you have a machine that fills soda bottles automatically, some of the bottles will have a little more soda in them and some a little less. If you measured the amount of the soda in the bottles and plotted it on a graph, you would find a normal distribution or bell-shaped curve. The peak of the curve is the average or mean.

The majority of the bottles will have 16 ounces of soda in them but some of the bottles will have a little more or a little less. Statistically, 99.7 percent of the bottles of soda will fall within six standard deviations, or Six Sigma, of the mean. The goal of the soda bottler is to have those standard deviations as small as possible. When the bottles come out the other end of the conveyor, you do not want them to be half full or overflowing. When the bottles are over or under filled, the process of bottling is out of tolerance.

Lean

Leaning is also a method of reducing the number of steps or making something more efficient. After Hurricane Katrina devastated New Orleans in 2005, it became apparent that the existing processes for response and recovery were very complex and convoluted.

Multiple agencies worked to help the people of Louisiana, but their efforts were not coordinated. Some areas received assistance from local, state, federal and non-governmental organizations (NGOs) such as Red Cross and other areas received little to no help. Military capabilities were not integrated effectively, response agencies were not able to communicate with each other and mass care and housing were disjointed to name a few.

Homeland Security and Counterterrorism completed a report “The Federal Response to Hurricane Katrina Lessons Learned,” with recommendations on how to lean the process of emergency response that has significantly reduced the confusion and improved the process – as seen by the response to Hurricane Irma.

Lean Six Sigma

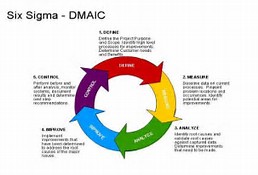

Lean Six Sigma (LSS) is the concept of combining Lean and Six Sigma. Lean focuses on the elimination of waste such as defects, overproduction, time, transportation, inventory, motion or extra processing. Six Sigma seeks to reduce the deviation in the product or service and increase the quality of the process outputs by removing the causes of defects and minimizing. LSS can be broken down into five steps.

- Define the problem. In our examples above, the problem could be too much/too little soda was put in the bottle or the response time and effectiveness of the federal government was too slow and failed the citizens of Louisiana.

- Quantify the problem by measuring or mapping the product/process. How much variance was in the amount of soda or how long did it take to get support to the Hurricane victims?

- Identify the cause of the problem through careful analysis. The soda bottler will look at their equipment and bottling process, and the federal government completed a study of what went wrong with the response to Hurricane Katrina.

- Implement the solutions. In our examples, the solutions would be changing the process/equipment in the bottling plant and reorganizing the federal response under the Federal Emergency Management Agency (FEMA).

- Maintain the solution by controlling the process. This can mean continuing to measure, analyze and improve the process to reducing the size of the deviations and improving the timeliness of the response.

Conclusion

Lean Six Sigma is a deliberate method of improving a product or service. When implemented correctly it will increase customer satisfaction, save time and money. That is why large and small businesses as well as government agencies have turned to the Lean Six Sigma (LSS) process to reduce waste, provide timely service and improve efficiency.

Stewart Fearon is part of the GovLoop Featured Blogger program, where we feature blog posts by government voices from all across the country (and world!). To see more Featured Blogger posts, click here.

Wonder if I can use LSS to get a better looking lawn ?

Great summary Stewart! I lead the Office of Continuous Improvement for the state of Minnesota. Our approach is to ‘solve problems that change lives’ – which means using all of the methodologies you mention, as well as the scientific method and design thinking!

These methodologies work well in the public sector to help make government services more efficient AND effective.

Thanks for highlighting this work!

Joe

http://www.mn.gov/ci