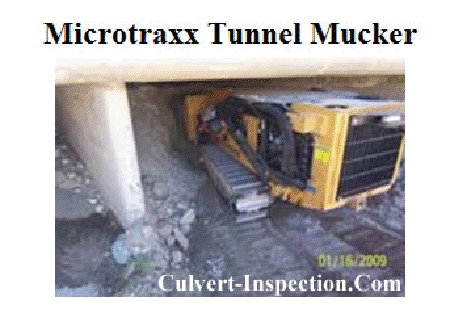

With budgets tight throughout the country and any serious economic recovery years away, states and municipalities are turning to technology to increase efficiency and save money. One example of innovation in action is the Mucker (its actual name is the Microtraxx Tunnel Mucker). The Mucker is used to excavate sediment from culverts and was created by the Advanced Highway Maintenance and Construction Technology Research Center at the University of California at Davis.

With budgets tight throughout the country and any serious economic recovery years away, states and municipalities are turning to technology to increase efficiency and save money. One example of innovation in action is the Mucker (its actual name is the Microtraxx Tunnel Mucker). The Mucker is used to excavate sediment from culverts and was created by the Advanced Highway Maintenance and Construction Technology Research Center at the University of California at Davis.The Mucker is a remotely controlled mini front loader, about 4-feet in height and width, and about 9-feet in length. The remote control allows the operator to stand in a location safely removed from moving machinery and exhaust fumes. Box culverts greater than 4-feet in height and circular culverts greater than 5-feet in diameter are possible candidates to be cleaned by the Mucker.

Generally, culverts are cleared with the use of vacuum trucks involving human entry into the culvert and large quantities of water to flush the soil sediment. Vacuum trucks are constrained to roadway shoulders and cannot be driven off road, and their use is limited to location that can be reached by the truck’s hydraulic boom. High pressure water is used to loosen the soil sediment, much like the hydraulic mining technics of the past. However, unlike the old hydraulic mining, all of the water used including the sediment is vacuumed up by the truck. None of the sediment or water is left in the stream channel.

The footprint of the Mucker operation usually determines where the Mucker can be used. The Mucker requires a relatively flat surface to operate. Wet or muddied stream beds require a base prepared so that the Mucker does not sink into the mud. The Mucker pivots 360-degrees on its base, so it requires an area of less than 10-feet in diameter to swing around and dump its load. A backhoe is used outside of the channel to scope the sediment and place it in a waiting dump truck. In some operations, where work space allows, a full-sized front loader can be used instead of a backhoe.

The Mucker has proven to be more efficient at clearing culverts than using vacuum trucks. Initial operational tests results show the Mucker performing the same duties of a vacuum truck 4 times faster. In other words, what would have taken a vacuum truck 4 days to accomplish, took the Mucker only one day. The rate of excavation using the Mucker was about 5 –10 yd3 per hour, with the rate varying depending on the length of the culvert and terrain.

The Mucker was originally developed to clear culverts of sediment and debris more efficiently. Operational test show the goal of efficiency has been achieved. However, in addition to efficiencies, the safety of culvert cleaning operation has also been improved. The remote control feature of the Mucker allows the operator to stand in a safe location outside of the culvert during the operation which reduces the need for confined space procedures and ventilation machinery.

About the author: Manuel Morales has been working in the public sector since 1994. He has been involved in coordinating and creating culvert inspection programs since 2001. Manuel’s blog can be found at Culvert-Inspection.Com

Leave a Reply

You must be logged in to post a comment.