All employees in every organization should have a basic understanding of process and system. This is a bold statement and may be too much to ask of all workplaces. However, every employee is a link in a chain of business activities which produce or provide a product or service. Thus, they are affected by others in the chain, and have an effect on others in the chain. The links in the chain are your processes, the sum of which creates your system.

All employees in every organization should have a basic understanding of process and system. This is a bold statement and may be too much to ask of all workplaces. However, every employee is a link in a chain of business activities which produce or provide a product or service. Thus, they are affected by others in the chain, and have an effect on others in the chain. The links in the chain are your processes, the sum of which creates your system.

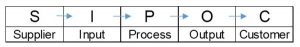

This does not mean that every member of your staff has to become process experts, nor must they seek six sigma certification. This is merely acknowledging that anyone on your team is likely part of a greater whole of interdependent activities. Therefore, they should have an awareness of the SIPOC relationship.

The significance of understanding SIPOC is that your employees are encouraged to think beyond their tasks to avoid having their thinking limited to their functional silo. Having familiarity with SIPOC, they realize that they rely on input from others (a supplier) and produce an output to another (their process customer). It is also helpful for them to see the recipient of their work as a “customer.”

It is a common limitation that employees who are trained to perform specific duties operate in a vacuum because they are either unaware of their impact on others, don’t see the connection between their performance and those to which they are linked, or dismiss the role they play in serving the ultimate consumer. Understanding their unit’s SIPOC helps workers to visualize themselves as one of many links—or perhaps gears may provide better imagery.

At any rate, process knowledge and system awareness allow workers to see beyond their immediate span of control, arming them with a broadened perspective of your business. Not only does this help them become better team players but enables them to see the business through the eyes of the customer.

Keep in mind that if a customer is unhappy with their product or service, they do not care where in the chain performance failed. They just know that the output they received is not acceptable and it’s the business’s responsibility to fix it. A process understanding allows employees anywhere in the chain to quickly narrow down the source, and get to the root of the problem. When employees are ignorant of the process, they simply acknowledge what’s not there’s and pass the buck. This does not lend to quality service or happy customers.

Consider offering a basic level process and systems training course to your entire team. Make certain to include multiple process partners in the same session so that they can see the benefit of gaining an understanding of their linked processes. Frequently, conducting such training opens up communication and provides useful insight to all persons involved.

Employers who educate their workforce in process and systems find greater effectiveness and efficiency, resulting in reduced costs and greater customer satisfaction. In addition, it fosters employee development, teamwork, and improved operational synergy which will create improved employee engagement and satisfaction. It’s a WIN – WIN – WIN!

Lori Okami is a GovLoop Featured Contributor. She has over nine years of experience in local and state government in Human Resources, grants management, and as an educator, as well as over twenty years in the private sector. Lori has written over 400 health and fitness blogs for Hawaii’s premiere online news publication. Lori’s expertise is in organization alignment, change management, and customer relationship management (CRM). You can read her posts here.

I wasn’t previously familiar with the SIPOC framework but this really nails it. It all ends with the customer, and no matter where you work an unhappy or underserved customer is mission failure. Training in a vacuum is never a good idea!

Hi Blake! Yes, we all need to keep the customer in mind, both our process customer and the ultimate consumer of whatever product or service we provide. Unfortunately, some workers lose sight of this. Appreciate your comment!